PT. Rekadaya Sarana Mukti Indonesia

Raising the bar for sand washing in Indonesia by transforming muddy feed into high-quality construction sand.

PT. Rekadaya Sarana Mukti (RSM), based in West Java, Indonesia, embarked on a mission to address a critical material supply issue that was impacting construction activity in and around Subang. The region’s readily available pit sand-naturally occurring but heavily laced with clay and silt-was unsellable in its raw form. Inadequate washing infrastructure, outdated local machinery, and an absence of sustainable practices across the Indonesian sand washing sector further compounded the problem. With no existing solution capable of producing ASTM C33 or SNI-compliant construction sand from such challenging feed, RSM’s leadership, including Mr. Zainur Akbari and Mr. Ridwan Suria, actively sought global technology leaders to bridge this gap.

Following site visits and product performance evaluations in India and Sri Lanka, the RSM team was introduced to CFlo’s Combo Alpha-i, a compact, high-efficiency sand washing system engineered to handle precisely such muddy, lumpy pit sand. After thorough lab testing of their material and confirmation that the system could meet their stringent product quality needs, RSM commissioned the Combo Alpha-i plant at their Bunihayu site in August 2018.

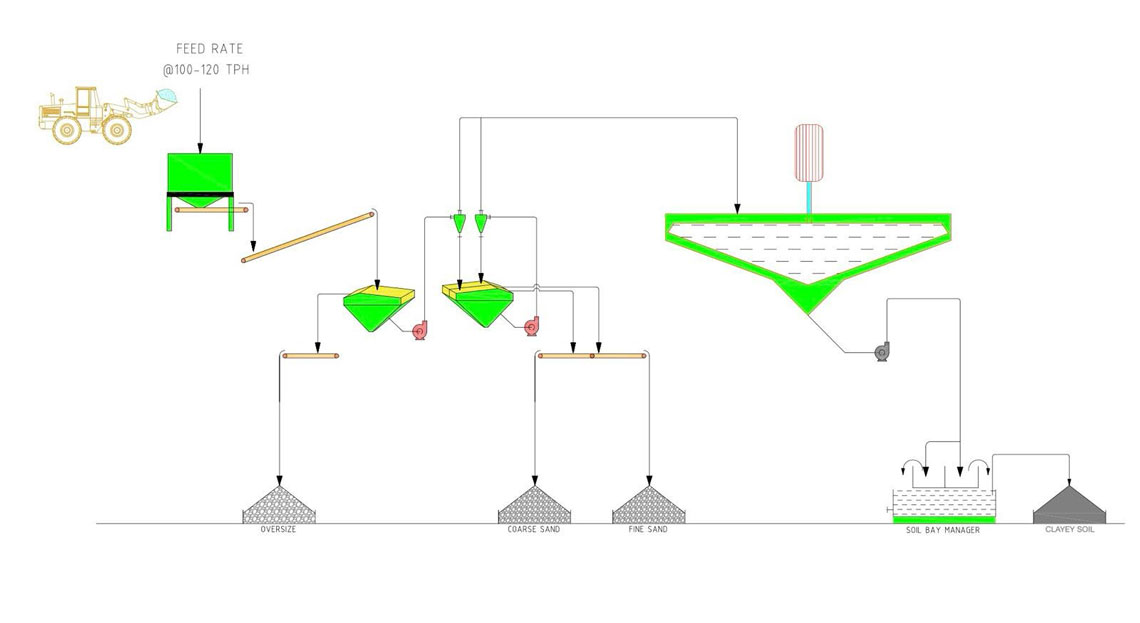

The raw material available at the site posed significant challenges: it contained high levels of silt (up to 25% of material was <75 microns), poor gradation, and sticky clay-bound fines. Combo Alpha-i’s Turbo Dual Washing Technology effectively addressed these issues. The system’s unique two-stage washing and high-pressure scrubbing mechanisms ensured that the raw feed was thoroughly liberated from contaminants and clay coatings, enabling consistent production of high-grade washed sand. Moreover, the system could handle a feed capacity of 100–120 tonnes per hour with minimal downtime, making it viable for continuous commercial-scale operations.

One of the standout features of the Combo Alpha-i solution was its ability to recover up to 95% of process water through an integrated water recycling system, dramatically reducing the plant’s fresh water requirement to just 16–19 cubic metres per hour. This was particularly important in an environment with growing scrutiny over water use and sustainability. The modular design of the plant allowed it to be installed within a compact footprint, avoiding the need for large settling ponds or sludge disposal zones, which are otherwise typical in traditional setups.

The plant’s integrated PLC-based automation enabled uninterrupted performance and minimal operator intervention.

The result has been the continuous production of three commercially valuable outputs:

Since its commissioning, the facility has clocked over 15,000 operating hours and processed more than 1.5 million metric tonnes of pit sand.

Initially, the client intended to produce only sand; however, due to the thorough washing and clean separation provided by the system, even the oversize and sludge streams found consistent market demand- particularly the sludge, which is now supplied to the ceramic industry.

This zero-waste approach has significantly elevated the business economics of the RSM operation. The washed sand commands a market rate of Rp. 161,000 per cubic meter, while the oversize aggregates are sold at Rp. 32,750 per cubic meter, and the clayey soil is monetized at Rp. 20,000 per cubic meter. The dependable quality of output has attracted clients from across West Java, including urban centers like Bandung, Karawang, and even Jakarta, further reinforcing the credibility and performance of the installation.

From the client’s perspective, CFlo’s Combo Alpha-i system was more than just a technology upgrade-it transformed the way the sand industry operated in Indonesia. By demonstrating that even highly problematic pit sand could be turned into valuable, specification-grade construction materials using a compact, eco-efficient solution, it challenged conventional thinking and raised the benchmark for sand processing across the region. It has also positioned PT. Rekadaya Sarana Mukti as a benchmark supplier of construction aggregates in the region.

We never imagined all three outputs could be sellable. Combo Alpha-i not only solved our technical challenges but gave us a profitable, sustainable business in Subang. It set a benchmark in the Indonesian market.

In summary, the successful deployment of CFlo’s Combo Alpha-i at the RSM site exemplifies the kind of innovation and engineering excellence that is reshaping sand processing practices across emerging markets. It proves that with the right engineering, even the most problematic feed materials can be converted into premium construction resources while ensuring sustainability, operational efficiency, and commercial viability.