CFlo teams up with Kumar Cargo Solutions to pioneer India's first overburden conversion project, repurposing Coal Overburden into high-quality graded M-Sand.

CFlo teams up with Kumar Cargo Solutions to pioneer India's first overburden conversion project, repurposing Coal Overburden into high-quality graded M-Sand. Through CFlo’s leading-edge technology, they established a sustainable solution that not only reduces environmental impact but also sets new benchmarks for eco-conscious mining.

With an impeccable 20-year track record in the mining and minerals industry, Kumar Cargo Solution is renowned as a reliable partner for Turnkey Contracts. Their commitment to process enhancement has forged a versatile portfolio of mining services, including long-term agreements, advanced technology solutions, Crushing and Screening, Mineral & Overburden Processing, Material Handling Services, and open-cast mining. KCS continues to deliver unmatched support to valued clients, solidifying its position as a trusted player in the industry.

Northern Coalfields Limited (NCL), one of India's leading coal-producing companies, a subsidiary of Coal India Limited, faced a pressing challenge with the overburden generated during mining operations. Committed to responsible mining and sustainability, NCL envisioned repurposing this overburden into valuable IS:383 grade sand.

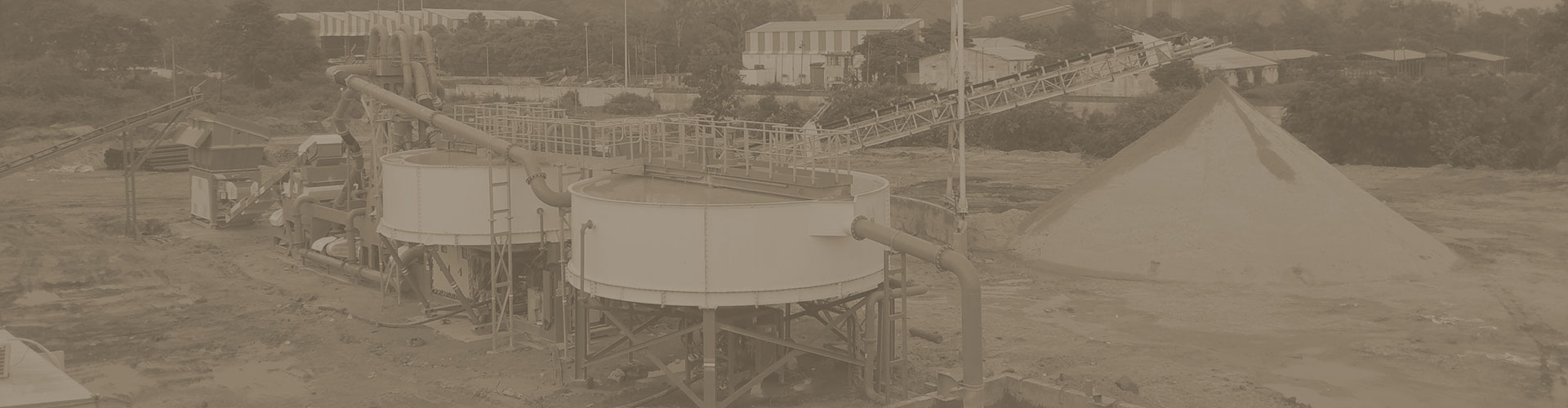

In a significant effort to promote ecological balance, NCL began a competitive process in partnership with the private sector (PPP) to establish a plant that separates sand and aggregates from Overburden (OB). In pursuit of their aspiring objective, KCS took a momentous leap by partnering with CFlo, to establish a state-of-the-art plant. Together, they harnessed their collective expertise to commission a cutting-edge 160-180 TPH Overburden to sand plant at NCL's site in Singrauli, Madhya Pradesh. This exceptional collaboration led to the commissioning of a groundbreaking facility, showcasing KCS's unwavering dedication to producing M-Sand from Coal Overburden.

Our Advanced Overburden Waste Processing Systems have been meticulously designed to tackle the pressing environmental challenges that enabled KCS to effectively recover sand from waste, presenting a sustainable and eco-friendly solution. The extracted sand possesses a wide range of applications in the construction industry, providing a responsible means to repurpose waste materials.

Our patented wet processing facility transforms high-silt mining overburden into graded M-Sand. We start by feeding - 5mm overburden into our state-of-the-art equipment, using dual-wash technology with Hydrocyclones to remove waste solids and enhance product quality. The material is then dewatered and screened for a low moisture finished product.

Our compact 160-180 TPH plant is all-in-one, reducing water usage by up to 95% through recycling, promoting sustainability. We strictly maintain a silt content limit of 4-5% for top product quality. Our systematic approach ensures efficient sand and silt management, wastewater control, and slurry management, solidifying our industry leadership in resource management.

We are proud to have collaborated with KCS on this ground-breaking project. Introducing our Advanced Overburden Waste Processing System to their operation was a game-changer. Witnessing the seamless conversion of coal overburden into graded M-Sand was truly remarkable and it is gratifying to see how our technology contributes to their commitment to sustainability and resource optimization.

The Overburden to M-Sand project with NCL is a remarkable pilot project by this Coal India subsidiary,showcasing our unique solution through KCS. Through our innovative solution, we're proud to be a key part of this groundbreaking initiative. We're producing eco-friendly M-Sand from Coal Overburden, showing our dedication to using resources wisely.

At the heart of this transformative journey lies a shared commitment to responsible practices, ensuring that our efforts not only conserve riverbed erosion but also preserve vital aquatic ecosystems. As we forge ahead, our dedication to sustainability remains unwavering, driving us to create positive impacts for the world we live in.