Afcons Infrastructure Limited is one of India's leading infrastructure development companies, with a proven track record of executing large- scale projects across more than 25 countries. They are currently a key player in the Samruddhi Mahamarg Expressway, one of India’s most ambitious infrastructure projects. This 701 km-long expressway will connect Nagpur and Mumbai, reducing the commute time from 14 hours to just 8 hours. Afcons’ vast experience spans across a diverse range of sectors, including highways, bridges, metro rail, and water supply systems.

The construction of the Samruddhi Mahamarg Expressway, especially Package 2, posed significant material processing challenges due to the scarcity of water at the work site. The scope of the project involved the construction of two interchanges, multiple flyovers, bridges, and several culverts, with specific demands for graded manufactured sand. To ensure the project’s progress and maintain the required material quality, Afcons sought a solution that could optimize material processing while utilizing minimal water, meeting the project requirements for graded manufactured sand.

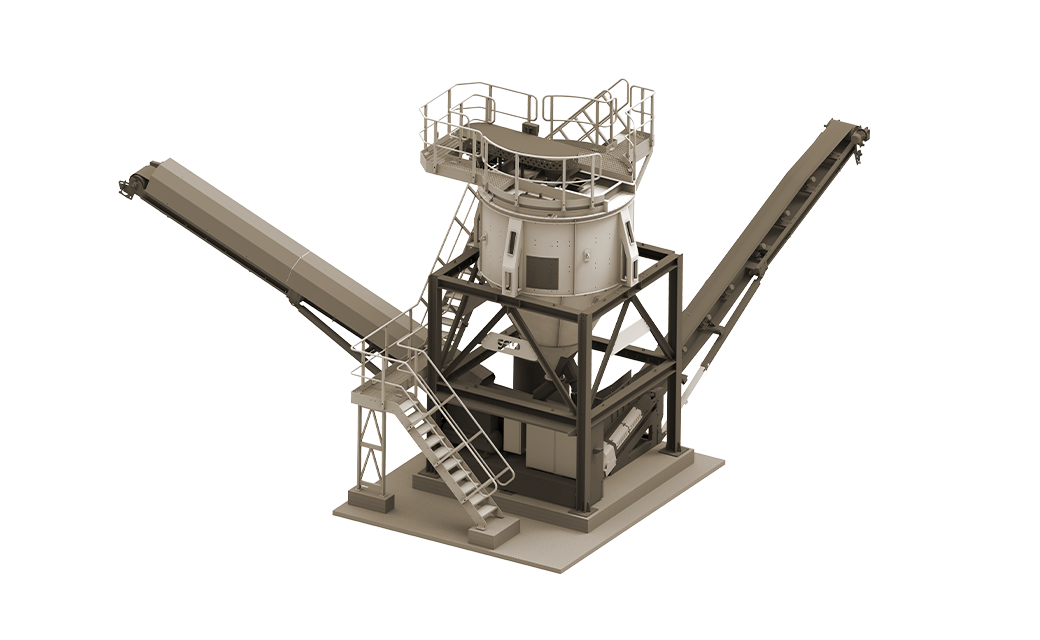

Understanding the need for an efficient air separation solution that complements the site's limited water availability, CFlo introduced Afcons to the Aerograder, a state-of-the-art air classification system designed for dry material separation. The Aerograder was selected for its capability to provide fine and coarse materials with high precision without the need for complex auxiliary equipment. The Aerograder operates with minimal power consumption-only 45 KW-making it one of the most energy- efficient systems in the industry.

With a feed capacity of 60-70 TPH, the Aerograder was integrated into Afcons’ existing circuit, including the feeding mechanism, product stockpile conveyor, and dust suppression system. The Aerograder ensured a continuous and uninterrupted production of high-quality manufactured sand with minimal waste.

The Aerograder was installed at the project site as part of Package 2, which involved critical infrastructure work in Khadki, Pimpalgaon, and Wardha. Given the constraints at the site, Afcons was able to leverage the Aerograder’s capabilities to produce dedusted manufactured sand without the availability of adequate processing water on site. The system’s modular design allowed for easy installation and customization, ensuring it met the specific requirements of Afcons for optimal material recovery with the limited water available at the site.

CFlo’s team worked closely with Afcons to ensure seamless installation and efficient integration into the project’s workflow. The Aerograder was able to perform reliably under pressure, meeting the project’s demanding timelines and material quality standards.

The Aerograder’s impact was far-reaching, enabling Afcons to achieve remarkable results on the Samruddhi Mahamarg Expressway project. The system’s ability to efficiently produce high-quality manufactured sand with minimal water usage was a game-changer, allowing Afcons to meet their project goals on time. The Aerograder does not require auxiliary equipment such as cyclones, baghouses, and external fans— typically required by other air classification systems—thereby reducing capital and operational costs while minimizing the footprint and execution complexities of the project.

Afcons Infrastructure successfully completed Package 2 of the Samruddhi Mahamarg Expressway well ahead of schedule, thanks to the availability of graded manufactured sand produced using the Aerograder. The solution played akey role in enabling Afcons to continue meeting their demanding project requirements.

We are delighted with the performance of CFlo's Aerograder on our Samruddhi Mahamarg project. The technology not only helped us save valuable water resources but also delivered consistent, high-quality graded manufactured sand. From timely equipment installation to the continuous production of uncompromised quality materials, CFlo’s team has proven their worth as pioneers in sustainable sand solutions. Their steady support and attention to detail made them a trusted partner on this significant project.

The Aerograder’s success on the Samruddhi Mahamarg Expressway is a testament to its ability to meet the evolving demands of modern infrastructure projects. By optimizing material recovery, reducing environmental impact, and offering a cost-effective, efficient solution, the Aerograder has proven itself as an invaluable tool for Afcons Infrastructure in their ongoing commitment to sustainable and high- quality infrastructure development.